Modern production environment

Optimum material flow with the SmartFlow effect.

Take your production environment to the next level with expertise from over 50 years of material flow design. The SmartFlow Team of experts will lead your project to success.

Blog

Three reasons to optimize your material flow.

Material flow - Not just faster, but better.

Blog

Three reasons to optimize your material flow.

Material flow - Not just faster, but better.

Problems

Frequently asked Questions from the industry.

How can I make my local production profitable?

Global supply chain issues are driving industry to produce locally again. To remain competitive, production environments must be optimized to the extent that production costs are kept as low as possible while maintaining fair labor costs and consistent quality.

How can my production environment be automated?

Not only because of the increase in profitability, but also because of the constant shortage of skilled workers, companies are nowadays forced to automate their processes and thus compensate for the lack of trained employees. However, this must be planned from the ground up.

How do I respond to constantly changing production cycles?

Nowadays, production cycles rarely remain at the same production level over a longer period of time. Product variants, tests, lack of success of the end products and many other things cause the production cycles to change constantly. It is always necessary to react to this at short notice without disrupting the flow of day-to-day business.

SmartFlow Effect

With the SmartFlow-Effect for a modern production environment.

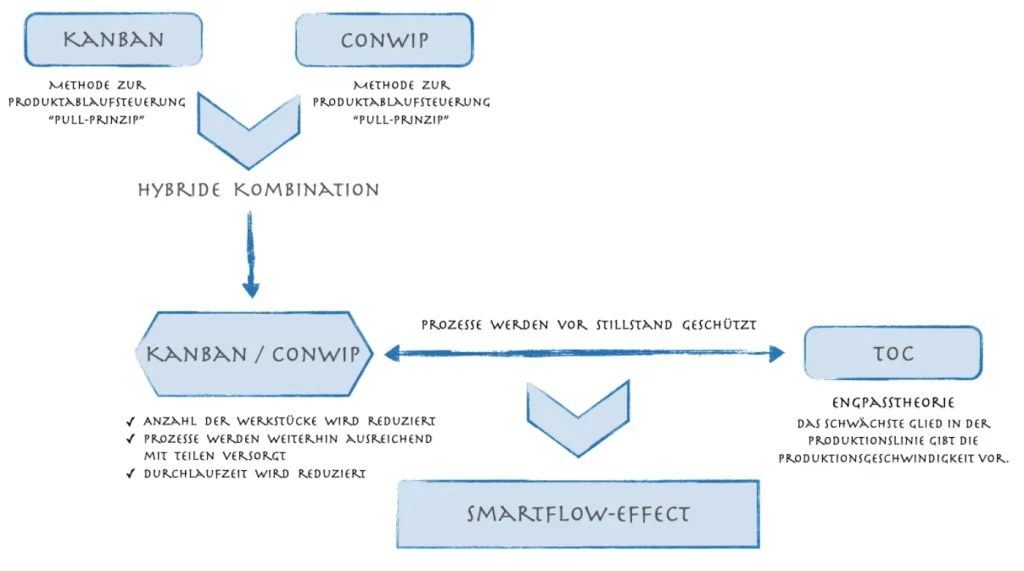

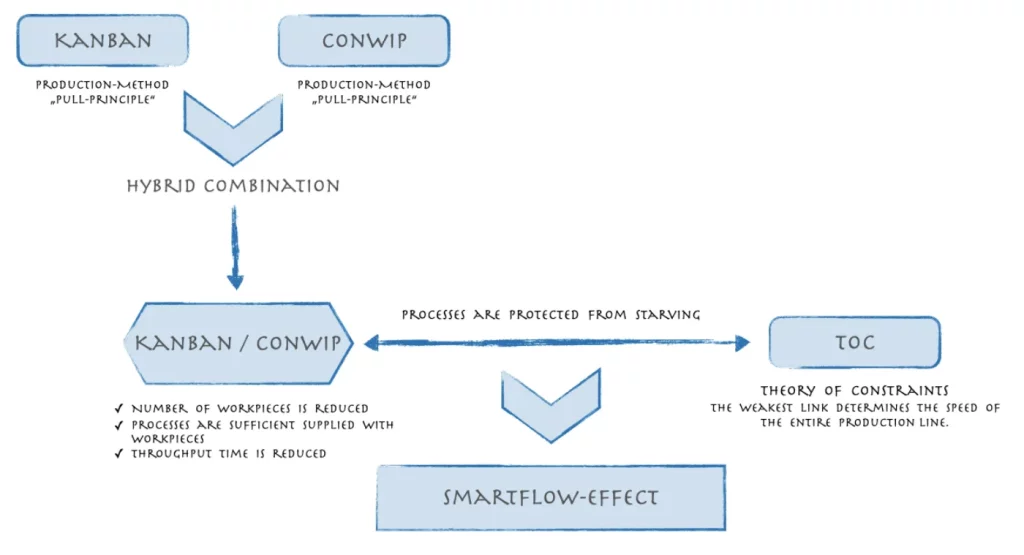

The SmartFlow effect is a hybrid combination of the Lean technique "Kanban", the Constant Work in Process "CONWIP" and the Theory of Constrains "ToC". The goal is to maintain a constant, low inventory level within a production line through the hybrid CONWIP/Kanban combination in an industrial production environment, thereby reducing the lead time of the workpieces to be manufactured. The addition of the Theory of Constrains (also called bottleneck theory) additionally ensures that production losses due to short-term failures of machines within the production are minimized or even eliminated in the best possible way.

Team

50 years Material flow concept.

With our SmartFlow Team of experts, you have half a decade of expertise in the optimization and control of modern production environments at your disposal. From simple to complex. From automotive to microchip. We lead you and your project to success

1-day training on the topics, Theory of Consrains, Material Flow Theories, Kanban / CONWIP, Supplychain and MRP.

Factory visit from our SmartFlow expert team and 2-day training on the topics from the Basic course for a deeper understanding of the philosophies and individual problem solving.

Individual and holistic support of a material flow project by our SmartFlow expert team - including the identification of the "weakest point", individual solution proposals for the elimination of production problems and the conception for the optimization of the entire production environment.

Knowledge

Our expertise.

Your results.

Further development of own knowledge.

Whether it's via a single blog article, 1-day training, or holistic mentoring, SmartFlow's team of experts can support your individual development on the topics you need every day.

More security for your planning

Want to feel more confident about building, upgrading or expanding your production environment? With the support of SmartFlow, you know exactly what you have to do.

Optimal material flow.

Independently identify the problems within your production and learn how to correct the errors and achieve an optimal material flow.

Lower operating costs.

Use your new insights to increase your production volume flexibility and overall profitability while reducing operating costs.

Blog

Further development brings success.

Want to learn more about material flow and optimizing production environments? Read on here.